Advancements in Building Information Modeling (BIM) have not only taken 3-D coordination to the next level, they are also changing the way teams design, build and collaborate.

Advancements in Building Information Modeling (BIM) have not only taken 3-D coordination to the next level, they are also changing the way teams design, build and collaborate.

W.M. Jordan Company is currently using BIM technology in some capacity on nearly every construction management project in progress. This technology is an excellent tool for maximizing efficiency, while improving our quality of work.

First of all, what exactly is BIM?

BIM technology tools are used to model structures before they are built. BIM is a digital representation of physical and functional characteristics of a facility. The model becomes a shared resource for information about a facility, serving as a basis for decisions throughout the life-cycle of the structure.

Key Benefits of BIM Technology

- Visualization

Visualization is the ultimate tool to convey a project outcome. BIM allows us to view every aspect in vivid 3-D, long before the structure is built. It analyzes and condenses information, allowing simulation of various aspects, from sunlight during different seasons to energy performance.

- Transforming complex building processes

Each change in design, scheduling or material is instantly available to every member of the building and design team. BIM tools allow different disciplines to share complex project models, facilitate integration of multiple disciplines, and simplify the design evolution processes. We are able to use a 3-D environment to coordinate the most complex and integral systems, including structural, mechanical, electrical, plumbing and fire protection components.

- Cost control

By eliminating conflicts between building systems early on, BIM technology results in a project with fewer changes and unanticipated challenges, faster delivery and lower costs. BIM can assist in calculating how proposed changes will affect costs and scheduling. By working out potential conflicts in a virtual environment, we often save time and money for a project, with little rework during construction. Early implementation of BIM helps reduce risk and boost profit margins.

- Collaboration and data management

Cloud-based collaboration and data management tools allow building teams, designers and subcontractors to interact with 3-D building models. Model data can be published to a secure site, along with tools for takeoffs, scheduling and estimating. All project information, models and details are accessible from anywhere, on any device, to any member of the team.

- Project turnover and facility maintenance

The benefits of BIM extend beyond the design and construction phases into optimizing building operations and maintenance. Should a building owner desire it, equipment models can be added to the operations and maintenance data given to the owner upon project completion. BIM capabilities allow warranty and maintenance schedules to correspond with BIM models through a tagging system. This gives warranty and maintenance staff a digital tool to easily locate submittals, warranties or maintenance requirements by scanning a physical tag through a smart phone or tablet.

How is W.M. Jordan using BIM?

W.M. Jordan Company was the construction manager for the Embassy Suites Hotel, located on the Wilmington Riverwalk lining the Cape Fear River. W.M. Jordan’s project engineer and BIM expert explains how the technology was used on this particular project.

According to our expert, the project went through many design permutations. The building changed from a concrete to a steel structure, drastically reducing the amount of ceiling space available for mechanical systems. With three separate kitchens, fitting in all of the mechanical, electrical and plumbing systems required for an eight-story building in the reduced space was a key challenge.

Knowing the vast number of changes made during the design process, W.M. Jordan and its subcontractors elected to take the 3-D architectural model and the 2-D mechanical, electrical, plumbing and fire protection drawings and model all of these in the BIM environment.

“Collaboration between the subcontractors and the designers was key in getting information turned around fast to be able to keep up with the construction schedule,” he explains.

Based on the contract documents, W. M. Jordan Company’s staff coordinates system details such as duct work, insulation and valves. Having shop drawings that provide elevations and dimensions for every piece of pipe in the building takes the guesswork out of installation and allows for accurate prefabrication of duct and pipework.

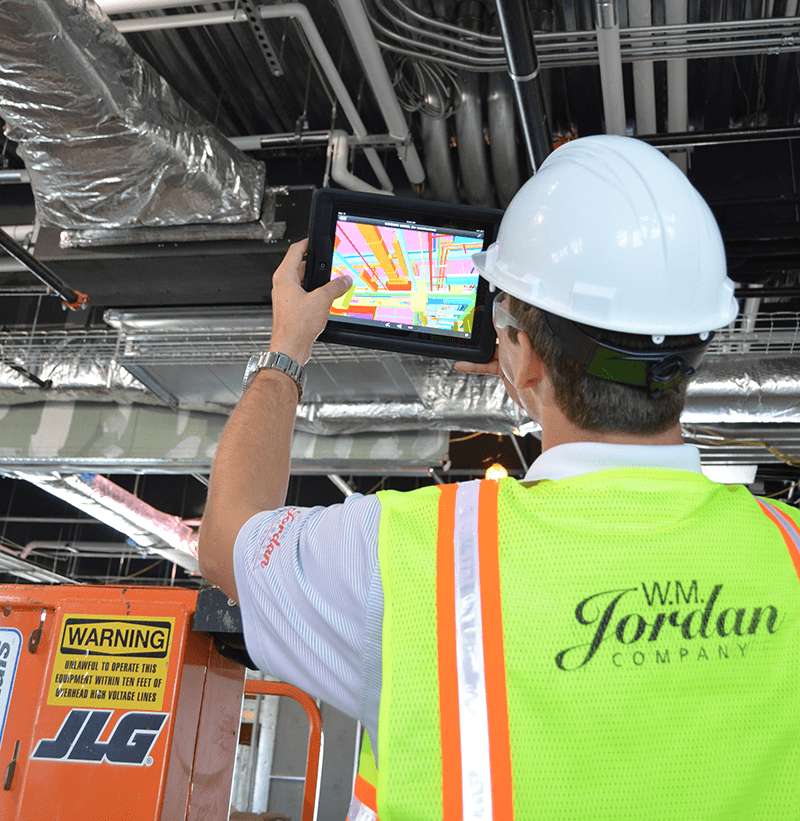

The fully coordinated model is imported to the field supervision and trade foremen’s electronic tablets. This allows foremen to better visualize the 2-D shop drawings, and can provide various installation dimensions. The models shown on the electronic tablets give installers a better idea of systems yet to be installed, preventing rework should the need for changes arise.

This coordination effort resulted in zero change orders for rework due to systems clashing in the field. We hope to see you on the Embassy Suites Wilmington Riverfront Hotel’s rooftop bar for cocktails with a view!